Lifting Hoist Buyers Guide

When you need a hoist for handling your heavy loads there are many options to choose from. Knowing what the options are can greatly influence your choice and determine its compatibility with your lifting task.

In our lifting hoist buyers guide we describe the basics on each type of hoist including some pro’s and con’s to help you with your selection.

Types of Lifting Hoist

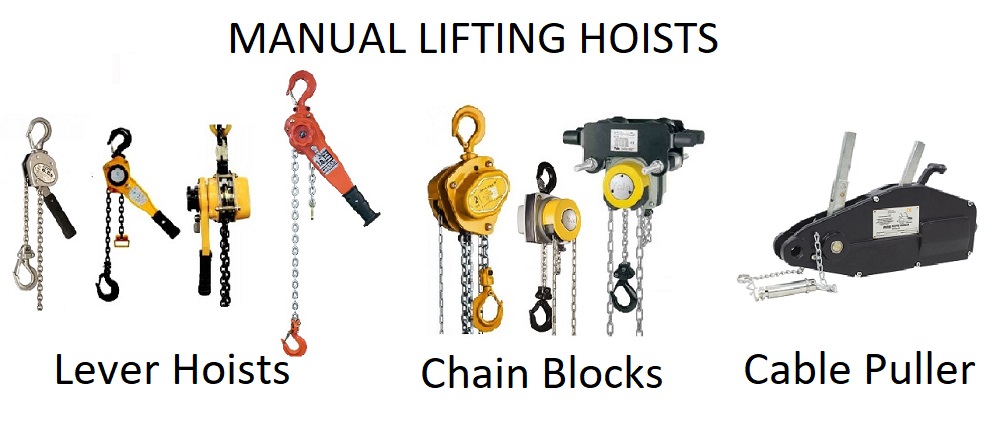

Firstly hoists can be split into two categories, manual hoists and powered hoists. Within the manual hoist category you will find the likes of manual chain blocks, lever hoists and cable pulling winches.

When it comes to powered hoists the options include electric or air powered varieties. There are numerous model types to suit different applications.

Most hoists incorporate a top hook for suspending from a suitable anchor point and a bottom hook for load attachment.

Lifting Hoist Buyers Guide details.

Let us now look at each type of hoist in a little more detail.

Manual Hoists

There are a couple of key benefits to using a manual hoist. Firstly and most obviously they require no power supply. So can be used in many more places when compared to powered hoists. Secondly they are easier to transport, thus can be kept in a work vehicle as part of your tool kit. Ideal for site work!

The downside to manual hoists is that they do require some physical effort in order to operate them. Whether its pulling down on a chain (chain block) or cranking a lever (lever hoist or cable puller).

Manual Chain Blocks

A manual chain block is quite simplistic in design, yet can lift extremely heavy loads. Often up to and above 20000kg, although the models which handle up to 5000kg are the most popular.

Using gears and a braking system, a steel hand chain is pulled to move the load chain over the gears. Thus increasing the power/force to lift the load. When the chain is released the brake will hold the load until operated again.

There are many different models from a variety of manufacturers to choose from, including the likes of Yale, Delta, Kito, GT, Hacketts and Raptor. Some have additional corrosion resistant protection which may be beneficial in certain environments.

Chain blocks are typically used by pulling the hand chain vertically, however models like the Yale 360 are capable of being operated from almost any angle, even directly above thanks to the hand chain rotation capability.

Lever Hoists

A lever hoist also uses gears to move the load chain, together with a pawl system the hand lever is ratcheted back and forth to pull the chain through the gears and subsequently lift the attached load. The key benefit to a ratchet lever hoist is that they can be operated in any position, thus ideal for pulling and tensioning tasks as well as lifting. Up to 9000kg can be handled with some models although they are more commonly used with lighter loads up to around 3000kg.

Cable Pullers

These cable pullers or winches are great for pulling and tensioning in any direction as well as lifting loads. They have a higher pulling capacity than the stated lifting capacity so ensure you check the details carefully. As an example a 1600kg model can lift up to this capacity, however it can pull up to 2600kg.

Powered Hoists

Electricity or pneumatic air power is required for this category of hoists.

Electric Hoists

Electric Hoists are the most commonly used powered hoists and come in many formats, so there should be one to suit most lifting operations.

Varieties include the more standard variety of electric chain hoists as well as scaffold hoists, stage hoists and ATEX hoists, plus wire rope hoists.

Each type is configured for specific lifting tasks; for example scaffold hoists are for use with scaffolding towers such as on a construction site; whereas a stage hoist is designed for use in the entertainment industry.

Wire rope hoists can usually handle the heaviest of loads and can be typically found on overhead gantry runway systems.

The electric hoists that can be used in a wide variety of environments and lifting applications come in a vast array of models from leading manufacturers, top picks include Delta, Yale, Stahl and Demag, but there are many more, equally as good.

These hoists are typically used in factories, manufacturing plants, engineering facilities, oil, gas, mining, shipping and more, there are even models specifically for use in wind turbines; the list goes on and on.

Pro’s & Con’s

One downside to these hoists is that they require an electric power supply, and not usually your typical household plug. 3 phase (400v) is the most common power type although there are other options including 110v, & 230v on some models. The power requirement could restrict where the hoist can be positioned.

Another potential pitfall is the initial outlay; they cost a fair amount more than a manual hoist, for obvious reasons, however depending on how it will be used, the cost can be recouped pretty quickly.

The biggest benefit to using an electric hoist is the ability to lift and move loads with little or no physical effort. This can have big benefits when it comes to health issues. The other key advantage is that they really do speed up the lifting process saving much time, effort and thus, money.

Air Hoists

Air hoists use a pneumatic, compressed air supply for operation. This type of power is not readily available in most environments like electricity is. Therefore an air hoist will need a dedicated air supply installed. On the up side once installed the hoist can operate at minimal cost (air supply equipment and tools up keep). Air is free – electric costs!

Air hoists are typically used in places where electricity is deemed hazardous. Areas such as paint factories, chemical plants, oil refineries and power plants all benefit from this type of hoist.

More Considerations

Once you have decided on the right type of hoist for your needs you will then need to consider the other options.

Safe working load lifting capacity, height of lift, any special features or extras you need such as a fitted trolley system, chain bag or add on tool.

It is also prudent to check the physical size and weight of the hoist to ensure it will fit and work as required.

Always purchase your hoist through a respected supplier for safety’s sake.

Remember, all hoists require thorough inspections at regular intervals according to LOLER (lifting operations and lifting equipment regulations).

Fast Delivery

Fast Delivery Low Prices

Low Prices Buy Online

Buy Online